Russia’s Superjet 100 and Il-114-300 Passenger Aircraft to be Showcased for the First Time in Wings India 2026

With a view to strengthening ties between the two close friends, India and Russia, Moscow has provided India with its Superjet-100-cla

There is no net or mesh on the front of the engine to stop birds, debris or objects from entering. Placing a mesh over an aircraft engine is a practical safety measure. Although the reasons for not using these are engineering, aerodynamics, performance efficiency, and aviation regulations. This blog will help you understand why a net or mesh is not placed in front of an aircraft to protect the engine.

Modern commercial aircraft engines need a continuous, clean airflow to function efficiently. For instance, engines such as CFM56 and Pratt & Whitney GTF, powering most of India’s Airbus A320 and Boeing737 fleets, are intended to take in over one ton of air per second at takeoff speeds.

Any impediment to this airflow can disrupt the calibrated internal aerodynamics of the engine. A mesh or net restricts airflow into the engine, causing turbulence that leads to a loss of engine performance and, in extreme cases, engine failure, particularly during takeoff and climb.

Fuel efficiency is a significant concern for airlines functioning in India, particularly low-cost carriers. In the Indian market, fuel accounts for nearly 40% of operational costs; even slight design inefficiencies can bring about substantial monetary losses. A net or mesh increases aerodynamic drag. This requires more thrust, resulting in higher fuel consumption.

Even a 1% increase in drag can cause a 0.75% growth in fuel consumption, as stated by International Aviation Research. For an airline operating an A320 aircraft across 8–10 sectors a day, this could translate into lakhs of rupees in extra fuel spending annually.

The idea of an ultra-light, strong mesh from carbon fibre or titanium might sound promising. Any protective structure strong enough to ricochet birds or debris at high speeds would have to be robust. Most bird strikes occur at about 460 km/h during takeoff or landing. A mesh that could endure such impact would add significant weight to the aircraft.

Every extra kilogram on an aircraft affects fuel efficiency. For instance, adding 100 kgs to an aircraft can surge annual fuel consumption by about 3,000 to 5,000 litres. This would translate to increased carbon emissions and higher operational costs, both of which are extremely undesirable in a market that is increasingly environmentally conscious and price-sensitive.

Bird strike is a big issue in the aviation sector. Airports, for example, IGI Airport in Delhi, Mumbai International Airport and Netaji Subhas Chandra Bose International Airport have all experienced several bird strike incidents over the years. As stated by data from the DGCA, India reported over 2,700 bird strike occurrences in 2023 alone.

These incidents are common during the monsoon and winter months. Airports surrounded by open waste dumps, wetlands or farmland are particularly prone to such occurrences. It may seem logical to install a mesh to avert birds from entering engines. Though aviation authorities, including the DGCA, follow International Civil Aviation Organization standards, which focus not on deterrence through barriers but on designing engines that are strong enough to endure bird ingestion.

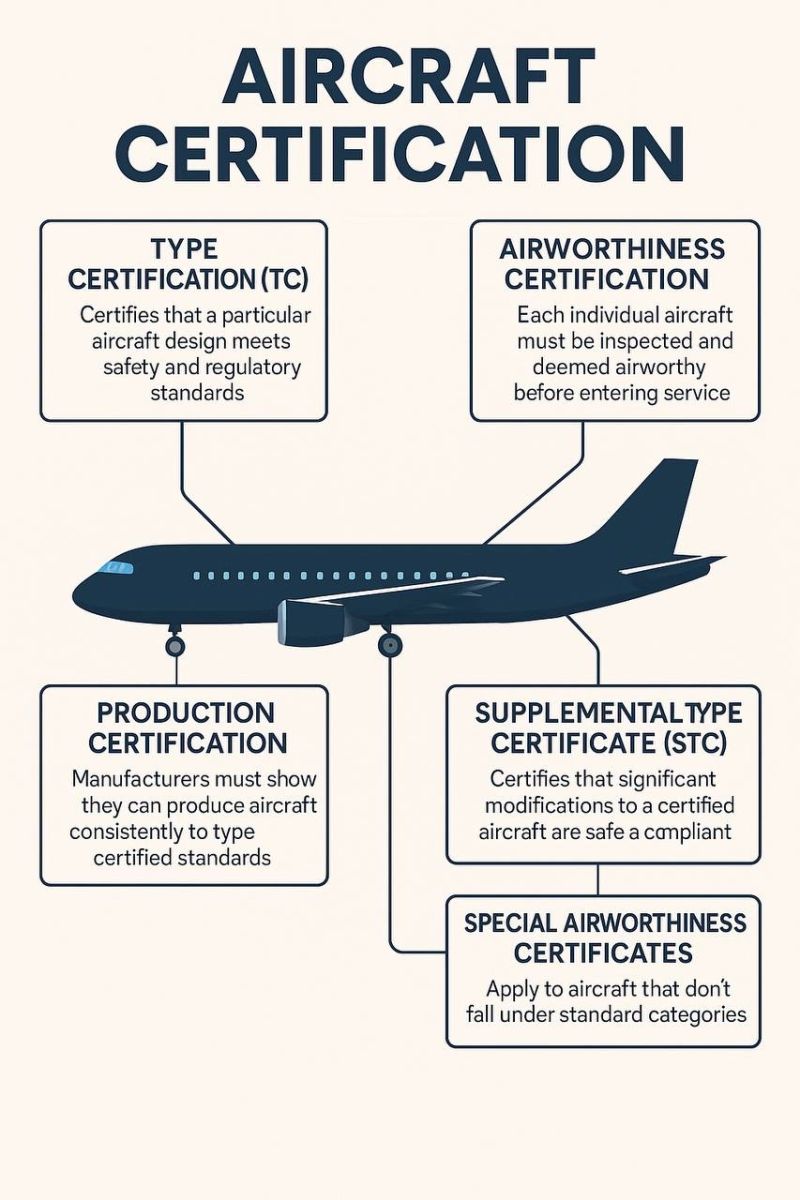

Aircraft engines undergo rigorous certification processes, such as the bird ingestion tests. Engines must ingest birds weighing up to 1.8 kg without failing. Throughout testing, dead birds are fired into an engine at high speed. These engines should function or shut down safely, as per ICAO and FAA regulations. Contemporary engines, such as the Leap-1A and Pratt & Whitney PW1100G, are made from advanced materials and fan blade containment systems, allowing them to absorb impact and minimize risk. So, a mesh or net is more hazardous and can cause damage to the engine.

Aircraft engines require regular inspections, particularly during pre-flight checks. A net or mesh blocks access to the engine’s fan blades, making inspection difficult. Any mesh will also deteriorate due to continuous exposure to high-velocity airflow, temperature fluctuations and vibrations. A damaged mesh could pose a greater hazard than the issue it was intended to prevent.

Some military aircraft use protective intake screens or particle separators. For instance, the HAL Dhruv helicopter features sand filters to operate effectively in desert environments.

However, the main difference is in speed and altitude. Helicopters work at far lower speeds and altitudes, and their airflow needs are dissimilar from those of high-bypass turbofan engines.

Likewise, some aircraft may use folding intake covers when taxiing on unpaved surfaces. These solutions are unfit for commercial planes, where even the slightest obstruction in airflow can lead to engine failure.

Instead of modifying engines, aviation authorities focus on practical bird control measures at airports. The Airports Authority of India (AAI) and private operators, such as GMR and the Adani Group, implement comprehensive Wildlife Hazard Management Programs.

These measures include habitat adjustments, the removal of open garbage dumps near airfields, regular patrolling, the use of bird-scaring devices, and even the deployment of trained falcons in high-risk zones. Moreover, most Indian airports now use cutting-edge runway sweepers to abate the existence of foreign object debris. Newer engines have fan blade containment rings, enhanced blade materials, for example, titanium composites and noise-reducing chevrons that also help uphold airflow stability.

The Indian aviation industry is experiencing rapid growth and is the world's third-largest market. Maintaining safety standards is paramount. Instead of relying on mechanical barriers, Indian aviation uses resilient engine design, strict certification protocols and inclusive wildlife management strategies. These offer a more effective alternative to the idea of placing a mesh in front of an aircraft's engine.

If you want to enter the aviation industry as a pilot, then you need to enroll in an aviation training academy like Flapone Aviation. Here, you will learn about all the theoretical as well as practical aspects of aviation. Then, what are you waiting for?

Connect with our aviation mentors to find the right path toward becoming a licensed aircraft pilot.