Airports of the Future: Smart and Autonomous Infrastructure

If you think that the aviation industry is free from challenges, then you are definitely on the wrong foot. This industry also faces challenge

Aeroplanes and space shuttles are not easy to get off the ground and keep off the ground. It takes a lot of energy, which means materials need to be light; it also takes speed to escape Earth’s gravity, meaning materials should be strong; travelling at the fringes of the atmosphere or in outer space includes exposure to higher radiation and extreme temperatures, meaning materials need to have properties enduring radiation and extreme temperatures.

Lighter and stronger materials give nations and private enterprises vital advantages when operating in aerospace. So, it’s perhaps no surprise that a lot of money has been spent on researching, developing, producing and improving aerospace materials.

Today, various cutting-edge aerospace materials are available for government, industrial, and even private use. Selecting the correct aerospace materials for a given enterprise can have important impacts on the outcome of that enterprise and fundamentally change its probability of success. Unfortunately, it can be overwhelming to determine which materials are correct for which endeavour. This blog will help you comprehend the development of aerospace materials over time, how they advanced, improved, and adapted to the market’s existing needs.

Material selection is important for aerospace applications because the extreme speeds, temperatures, radiation, material stresses, and other factors inherent in aerospace travel require materials that won’t break apart while flying through the air or burn up upon reentry into the atmosphere. Aside from the safety elements, some lighter and stronger materials can be more financially efficient to use from a fuel cost standpoint.

Qualifying materials for aerospace applications first requires determining which physical properties are essential for the specific application and verifying whether obtainable materials possess those properties to an acceptable degree.

Aerospace materials testing includes quantifying those properties. For instance, manufacturers or researchers test for things like fracture, compression, fatigue, impact resistance and others. Quantitative values, such as the pounds per square inch a material can withstand, are recorded and compared with the acceptable levels for several forms of aerospace travel.

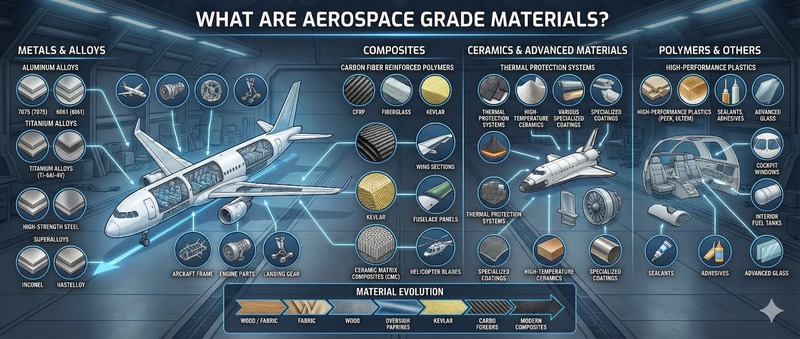

“Aerospace grade” means that the applicable material or process is appropriate for use in aircraft, which could mean helicopters, satellites, planes, drones or other aircraft. Given the rigours of aerospace travel, this fundamentally means materials that can withstand those rigours.

Aerospace-grade materials are consequently those that have high strength-to-weight ratios, corrosion resistance, and additional qualities appropriate for use in aircraft. Materials appropriate for use in a helicopter might not be appropriate for use in a commercial jet.

There are various aerospace materials in use today and some that have been used for over a hundred years. These might be special chemical compounds, such as composites, or particularly high-quality subsets of specific materials, such as aerospace-grade aluminium or titanium.

Some of the most significant aerospace materials include:

Researchers are looking for better composites and alloys, lighter, stronger, cheaper, less prone to erosion and superior in various other aspects.

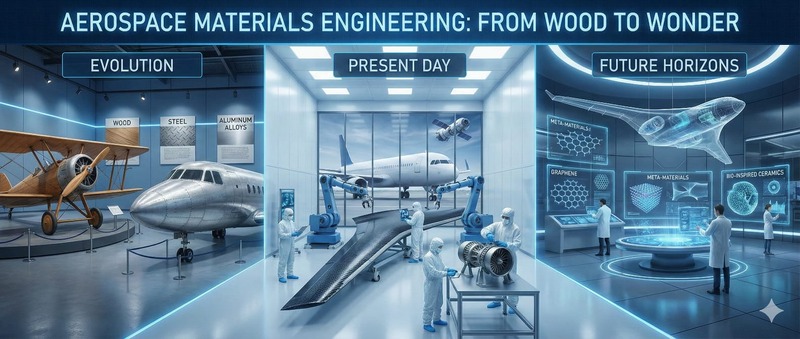

Historically, various materials have been used in aerospace travel. Early aircraft were made of wood, fabric and twine. As aerospace technology advanced, metals such as steel and aluminum allowed aircraft to significantly increase performance.

Aircraft Aluminum

Aluminium is ideal for aerospace because it’s not just light and strong but also extremely resistant to corrosion. It is also very strong in the face of UV radiation, which is mainly significant as crafts reach better elevations or leave Earth’s atmosphere altogether.

Aluminium is also abundant on Earth, making up somewhat over 8 per cent of the Earth’s crust. This means it’s comparatively cheap compared to steel and particularly to titanium.

Aerospace Alloys

Early aviation innovators were quick to discover the use of aluminium alloys in improving the quality of aerospace materials.

Titanium in the Aerospace Industry

Titanium and its alloys are used in aerospace applications owing to their properties. This metal has a great strength-to-weight ratio and can stand tall against corrosion. Titanium is also durable in extreme outer-space environments, making it an asset to the evolution of space exploration.

Composite Materials in Aerospace

Metals are not just materials useful for or extensively used in the aerospace industry. Another category of aerospace materials is composites. They are materials with two or more materials whose strengths complement one another and compensate for characteristic weaknesses of the materials when used individually. Common composites include particleboard and steel-reinforced concrete.

There are three types of composites, such as carbon fiber, glass and aramid-reinforced epoxy. There are others as well.

While engineers and researchers have developed some aerospace materials, the search for better options continues. Research is constant on diverse alloys and composites to produce stronger, lighter and more corrosion-resistant materials.

Nanoparticles

Nanoparticles are sized between atoms and molecules and are between 1 and 100 nanometers in diameter. Nanoparticles’ small size gives them exclusive properties and applications, for example, the ability to saturate larger, bulk materials to generate a kind of composite, for instance, metal-matrix nanocomposites.

Graphene

It is another promising material that is increasingly important in the aerospace industry. Many individuals are perhaps most familiar with graphene from its use in pencil “lead.” Graphene’s future use in aerospace goes far beyond pencils. This material’s shape also makes it an outstanding electrical conductor, which might lend itself to more than a few uses in support of the several electronic equipment necessary in contemporary and future aircraft.

Aerospace materials engineering is an extremely specialized field. Aerospace engineers need to not just understand various aerospace materials existing but also how those materials can be used in aeroplanes to make the best use of competence, performance and above all, safety.

Early aviation relied on tools that had been used by humans for millennia, such as wood, twine, fabric, etc. With the demand for aerospace travel increasing and aerospace technologies improving, metals, metal alloys and several types of composites have become vital to the aerospace industry. Extensive research and testing continue to strive for ever-greater aerospace materials to continue to drive human endeavours in aerospace.

The aviation world has come a long way of late. The aircraft materials and structural designs have transformed like anything. If you want to learn to pilot, then you can come to us at FlapOne Aviation.

Whether you're aiming to be a pilot or aviation expert, we’re here to help you choose the right aviation path.